Welcome to the world of limitless possibilities with custom plastic injection molding! Imagine having the power to bring your unique product ideas to life with precision and efficiency. In this blog post, we will delve into the fascinating realm of tailored excellence in mastering custom plastic injection molding techniques. From the design process to advanced applications and real-life success stories, get ready to be inspired by the endless potential of custom plastic injection molding. Let’s dive in.

The Design Process for Custom Plastic Injection Molding

When it comes to custom plastic injection molding, the design process is where innovation takes shape. It all begins with a concept or idea that is translated into a 3D CAD model. This digital representation serves as the blueprint for creating the mold that will bring your vision to life.

Next, meticulous attention is paid to every detail of the design, ensuring optimal functionality and manufacturability. Factors like wall thickness, draft angles, and parting lines are carefully considered to achieve the desired outcome.

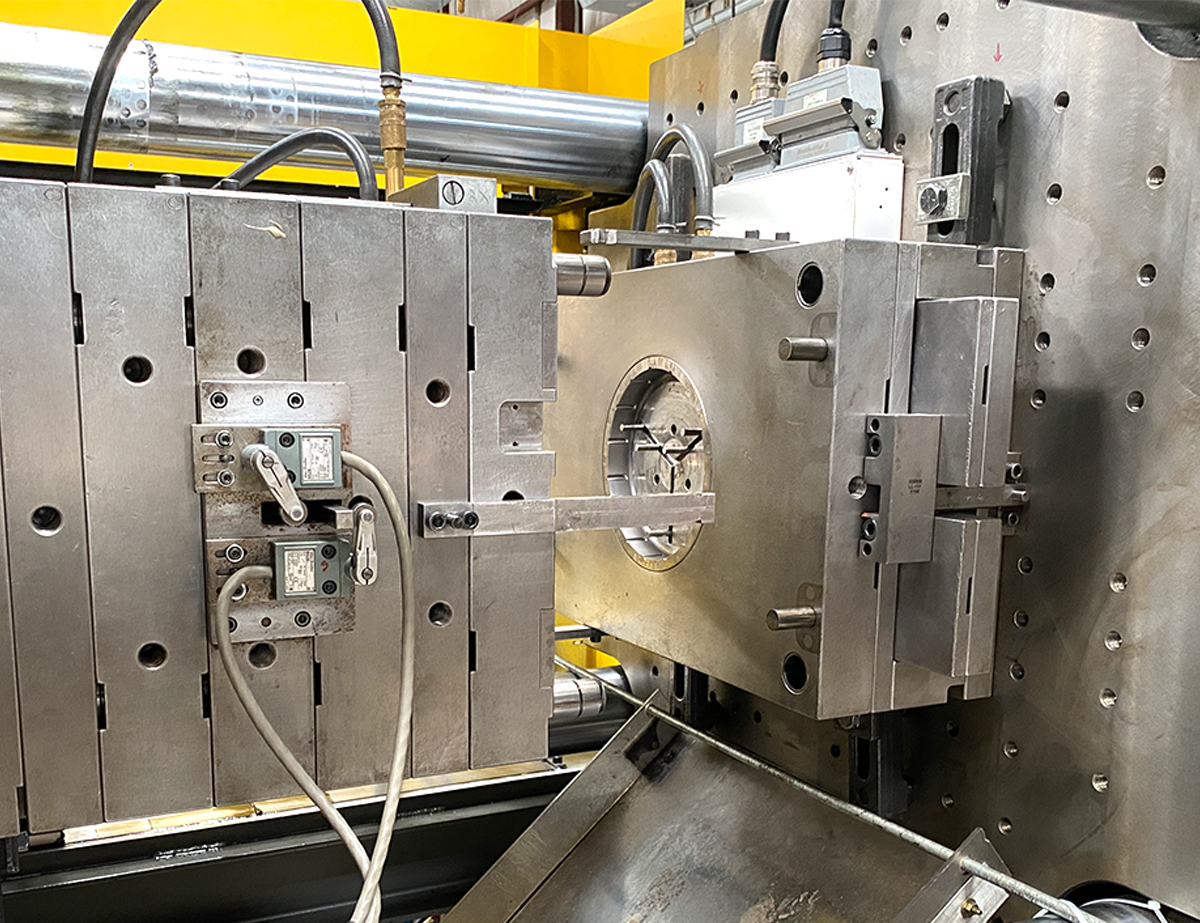

Once the design is finalized, precision tooling is created using CNC machining techniques. The mold must be crafted with utmost accuracy to ensure consistent and high-quality production runs.

Throughout the entire design process, collaboration between designers, engineers, and manufacturers is crucial for seamless execution. By leveraging expertise in material selection and manufacturing processes early on, potential issues can be identified and addressed proactively.

Advanced Techniques in Custom Plastic Injection Molding

When it comes to custom Custom Plastic Injection Molding, advanced techniques play a crucial role in achieving precision and efficiency. One of the key techniques used is scientific molding, which involves closely monitoring and controlling every aspect of the molding process to ensure consistent and high-quality results.

Another advanced technique is gas-assisted injection molding, which allows for the production of complex parts with hollow sections or thick walls. By using nitrogen gas to help fill out the mold cavity, this method reduces material usage and minimizes warping.

Furthermore, overmolding is a technique that involves injecting multiple materials into a single mold to create products with different textures or colors. This process adds versatility and aesthetic appeal to the final product.

Common Applications for Custom Plastic Injection Molding

Custom plastic injection molding is a versatile manufacturing process that finds applications across various industries. One common application is in the automotive sector, where custom plastic components are used for interior and exterior parts like dashboards, bumpers, and panels. These components can be precisely designed to fit specific vehicle models, enhancing both aesthetics and functionality.

Another prevalent use of custom plastic injection molding is in the medical field. Medical devices such as syringes, IV connectors, and surgical instruments often rely on this technique for producing high-quality, sterile components with tight tolerances. The ability to create complex shapes and intricate details makes custom plastic injection molding well-suited for meeting the stringent requirements of the medical industry.

Furthermore, consumer electronics benefit greatly from custom plastic injection molding processes. From smartphone cases to computer peripherals, manufacturers can produce durable yet lightweight components that meet design specifications while maintaining cost-effectiveness. This method allows for rapid prototyping and efficient production of electronic gadgets that require precise dimensions and finishes tailored to consumer preferences.